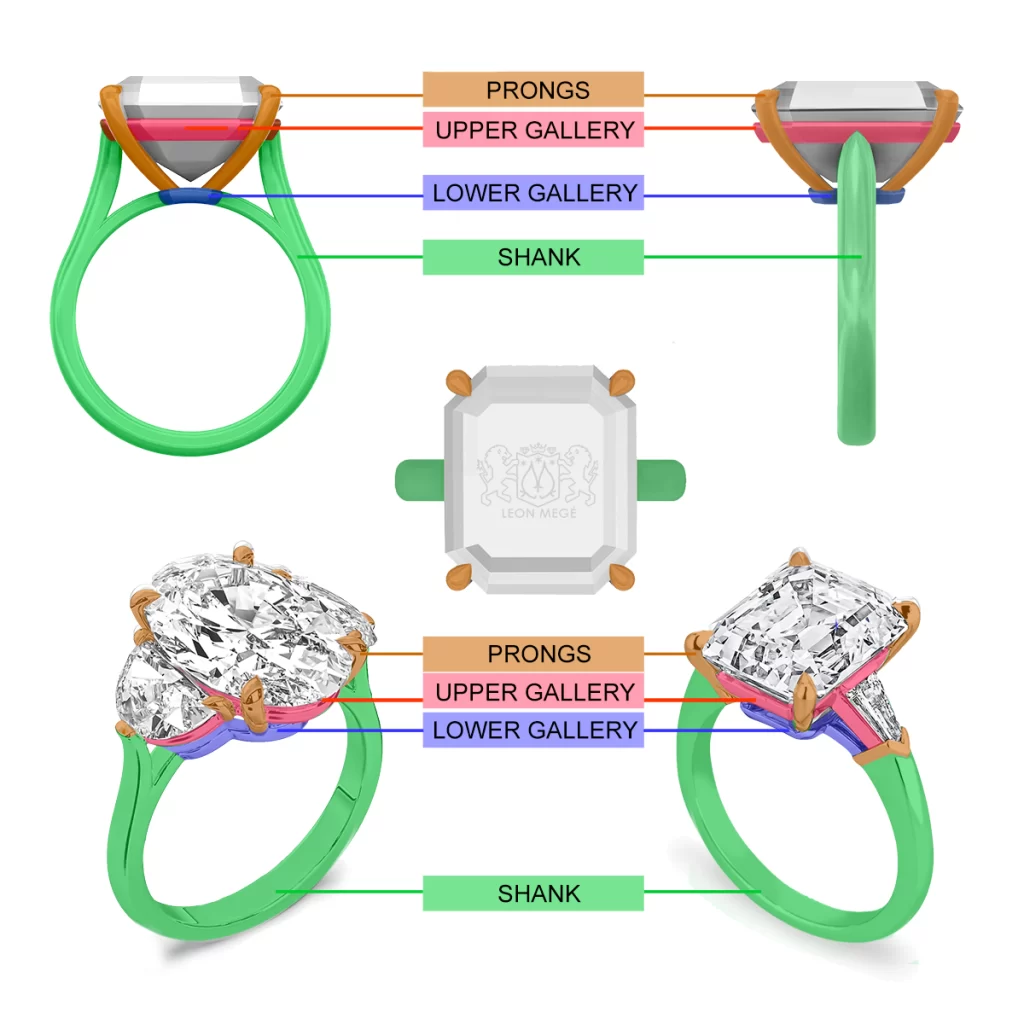

- Ring parts

- Prongs

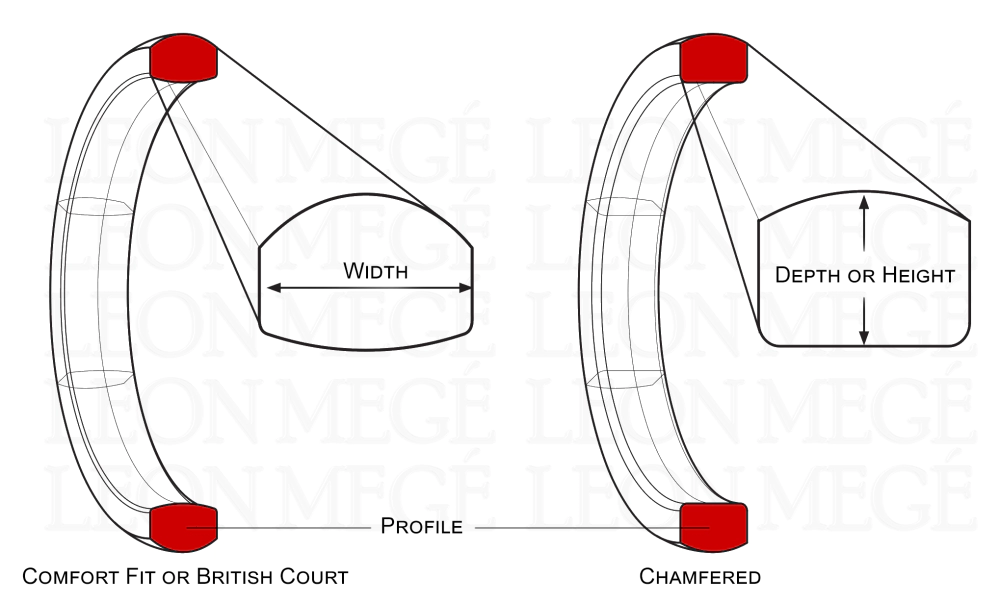

- Shanks

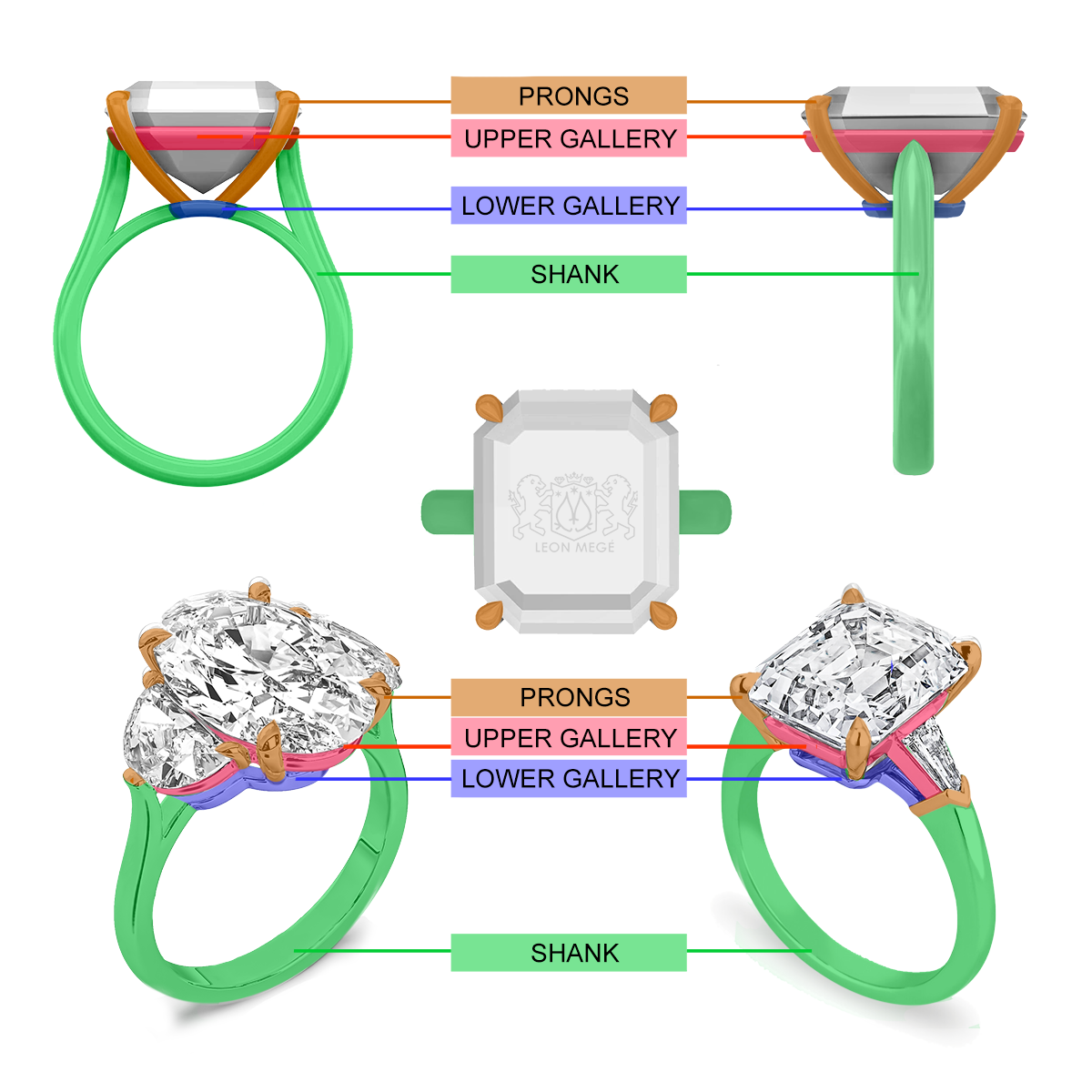

Knowing the ring parts is the key to understanding a design. Unfortunately, most jewelry terms are inconsistent, which makes it difficult to discuss the design. The brief glossary courtesy of Leon Mege Center for Advanced Jewelry Studies will help to communicate with us.

Shank

Most rings have two main parts: the head and the shank. The ring’s head plays a critical role in overall design, as it usually houses the center stone. The shank is the part that securely fastens the head of the ring to the finger. In certain ring types, such as a signet ring, there is no clear separation between the head and the shank. It is impossible to tell where one starts or ends. Shanks can be

- Cathedral (with an upward split)

- Raised (the height increases towards the top)

- Uniform (equal width and height, similar to the band)

- Flared (increased width and height towards the top)

- Counter shank (sometimes called Euro style, where the shank gets thicker and wider towards the bottom)

- Knife edge (wedge profile)

Band

A band is a metal strip of uniform width, height, and profile folded into a circle that can be set with diamonds, gemstones, or left plain. A band with a decorative attachment designed to be the focal point becomes a ring. A band that is a part of a ring is called a shank. Without a head, the band is an independent piece of jewelry, a wedding band being the best example.

Head, Basket, or a Mount

The head is the s ring’s focal point that holds a center stone or an arrangement of several stones. It can be a single setting, as in a Tiffany-style solitaire, or an elaborate assembly of many parts, such as prongs, stems, halos, galleries, baskets, and bezels.

Using terms like “Donut” or “Bagel” instead of “gallery” is unprofessional

Upper Gallery, Box, or Upper bezel

The basket structure supporting stones have different tiers, usually two. The upper gallery is the top tier of the basket, designed to provide a comfortable nesting area for the stones. In addition to serving as a stone “seat,” the upper gallery prevents prongs from moving laterally and ensures all stones remain in their respective positions permanently.

Lower Gallery, or a Bridge

The lower gallery is the foundation of the ring’s head. It is the base where prongs and stems converge. Its shape is usually a slice of the inverted cone or a pyramid with a base ring’s head outline. In solitaires, the gallery usually shadows the shape of the stone. The gallery size is determined by the prongs’ angle and the distance between the girdle and the finger.

Halo

A halo is made of diamonds or gemstones surrounding the center stone. A halo blends in with the center stone, creating a bigger look or framing the view, bringing the center stone into focus. A hidden halo is not a halo but an upper gallery set with diamonds. A hidden halo does not exist; it is a myth, much like the Yeti or his North American cousin, the Sasquatch.

Stems

Stems are pillars supporting a halo. In their most basic form, stems are made of round wire but can have any profile. Unlike building columns, stems are usually curved in or out and often tapered. Stems are often set with diamond pave.

Shoulders

Parts of a shank that are directly attached to the ring’s head. The cathedral shank’s shoulders are split from the base, so the bottom part of the split is connected to a lower gallery and the top part to the upper gallery. The shoulders are often set with diamonds to minimize the appearance of the bare metal.

East-West or North-South

Most center stones are aligned with the finger in a “North-South” direction. The “East-West” rings have the center stone set across the finger. They are less common and better suited for slim, elongated stones. The East-West rings work better with long and relatively flat stones. For the best result, the stone’s length should be roughly equal to the width of the finger.

Prongs are small hooks holding stones securely and with minimum obstruction. Prongs grip stones with their tips folded over the girdle. They converge under the stone to form a basket. The prong setting is the most popular way of setting diamonds and gemstones. Prong tips can be fashioned into claws, balls, or other shapes varying in width and thickness depending on the stone size and girdle geometry.

The prongs are the most effective way to secure gemstones with minimum metal visibility providing a high level of security. No prong setting is completely foolproof. A gemstone can fall out if the prong bends or breaks. However, a well-made and properly fitted setting significantly reduces the chance of this happening. A regular inspection by a qualified jeweler will help to identify any potential problems before a stone is lost.

A bezel setting can be considered the safest way to secure a stone because it wraps the entire girdle with metal. Unfortunately, it changes the look of the stone and makes it appear smaller by covering a significant area.

The prong setting provides a because it provides a good balance of security and visibility for the desired effect of the stone hovering in thin air without noticeable support. Expertly shaped prong tips are nearly invisible, the goal of fine jewelry.

Round prongs

Ball-shaped round prongs are the most common type found in jewelry. They are finished with spherical tips that even a beginner can repeatedly replicate with a beading tool. When looking down at the stone, the prongs look like small beads hugging the edge of the stone. As the stone size increases, the round prongs give way to claw prongs that are less pronounced.

They are rarely used for setting large stones in high-end jewelry. On the other hand, small stones are often set with ball prongs. Center stones set with round prongs are a telltale sign of commercial-grade jewelry.

Claw prongs

Claw prongs are shaped like pointy talons. The claw shape makes them nearly invisible. Unlike round prongs, shaped with a rotary tool, the claw prongs are painstakingly finished by hand using files and grinding wheels. Filing requires a lot of experience and takes time. It is physically impossible to maintain a consistent shape during mass production. It takes a lot of experience and know-how to finish a perfect “eagle-claw” prong. Much of the appeal of Leon Mege jewelry is in the ideal shape of our eagle-claw prongs

Swiss (tab) prongs

Flat prongs are the oldest type of prongs; they represent an evolution of the bezel setting. Flat prongs are narrow strips of metal left between sections of the bezel removed to let in more light.

The prong tips are shaped like flattened pyramids with sliced-off tops. Flat prongs have a rectangular cross-section as opposed to round-wire prongs. Flat prongs were popular during the Art-Deco period. Crown-style settings such as Tiffany solitaires are usually finished with flat prongs.

V-prong

V-prongs are typically used for stones with pointed ends, such as marquise, pear, heart, and princess cuts. V-prongs are designed to emphasize their sharp corners to help distinguish them from similar-looking shapes: marquises from ovals, Princesses from Radiants and cushions, etc. Both C- and V-prongs can be flat or rounded on the top. The prongs complement the stone, adding clarity to its shape and making it more pronounced. V-prongs are typically used for smaller stones. V-prongs provide extra protection to the most delicate part of a stone by evenly distributing the pressure over the wider surface, which helps prevent chipping and breakage.