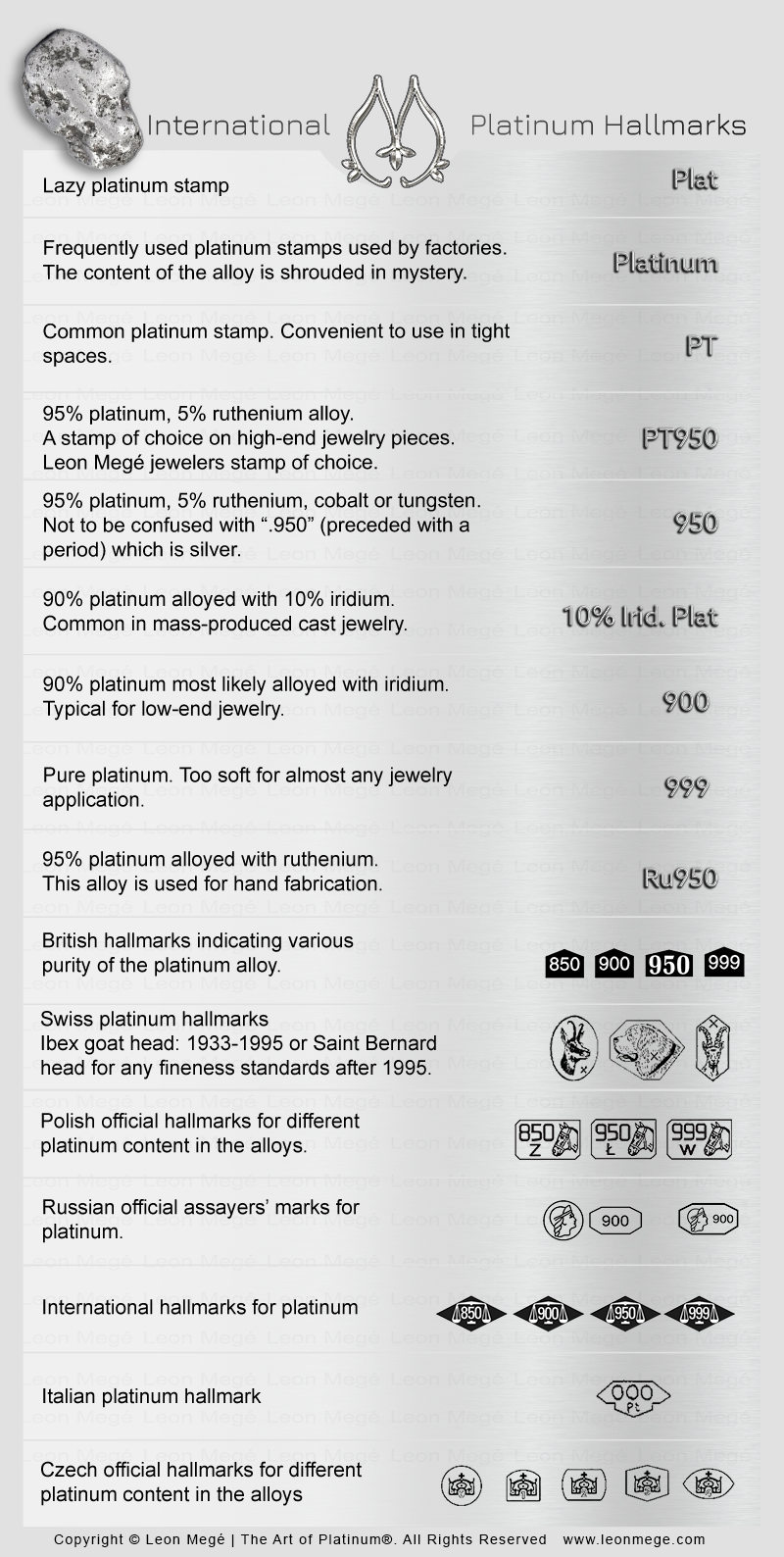

At Leon Mege, we use the following stamps on our jewelry:

- A serial number to ensure authenticity, identity, and ownership

- Metal: “PT950” for platinum, “750” for 18K gold.

- Maker’s mark: either the “M-logo,” “Leon Megé,” or both

Some stamps can be omitted if the physical space to put them is limited. When necessary, a laser inscription can substitute the hand-struck marking. Irregularities in hand-stamped hallmarks are acceptable and give your jewelry an authentic look.

Hallmarks' history

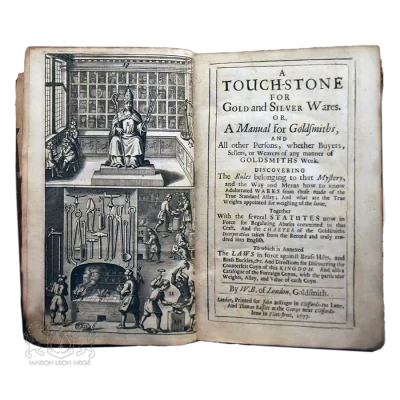

‘no goldsmith… shall from henceforth make or cause to be made any manner of vessel, jewel or any other thing of gold or silver except it be of the true alloy […] and that no manner of vessel of silver depart out of the hands of the workers, until further, that it be marked with the leopard’s head’. Statute of Edward I in 1300

Statute of Edward I in 1300

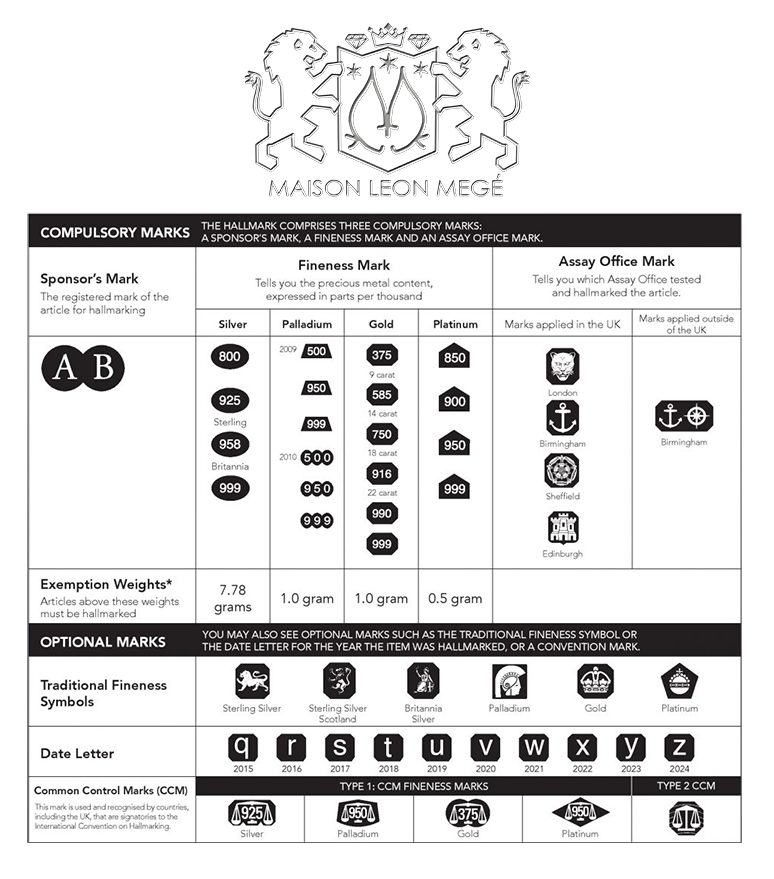

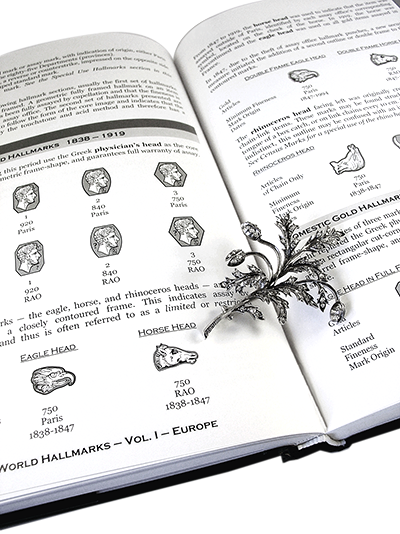

The history of jewelry hallmarks dates back to the Middle Ages when governments began requiring goldsmiths to mark their work with proof of its quality as a protection against counterfeit or low-quality jewelry. The first known hallmarking was established in England in 1238 when King Henry III decreed that all silver jewelry must be marked with the city of London’s coat of arms. This was followed by similar laws in France, Germany, and Italy. In the 16th century, hallmarking began to spread to the Americas. The first American hallmarking laws were passed in Massachusetts in 1641 and Virginia in 1661. Today, hallmarking is still required in many countries around the world. The marks vary from country to country but typically include a symbol representing the government or assay office that tested the jewelry, a mark indicating the metal content, and the maker’s mark. Hallmarks assure consumers the item meets certain quality standards and establishes precious metal content. Hallmarks can also help to identify the maker, which can be important for jewelry collectors and curators.

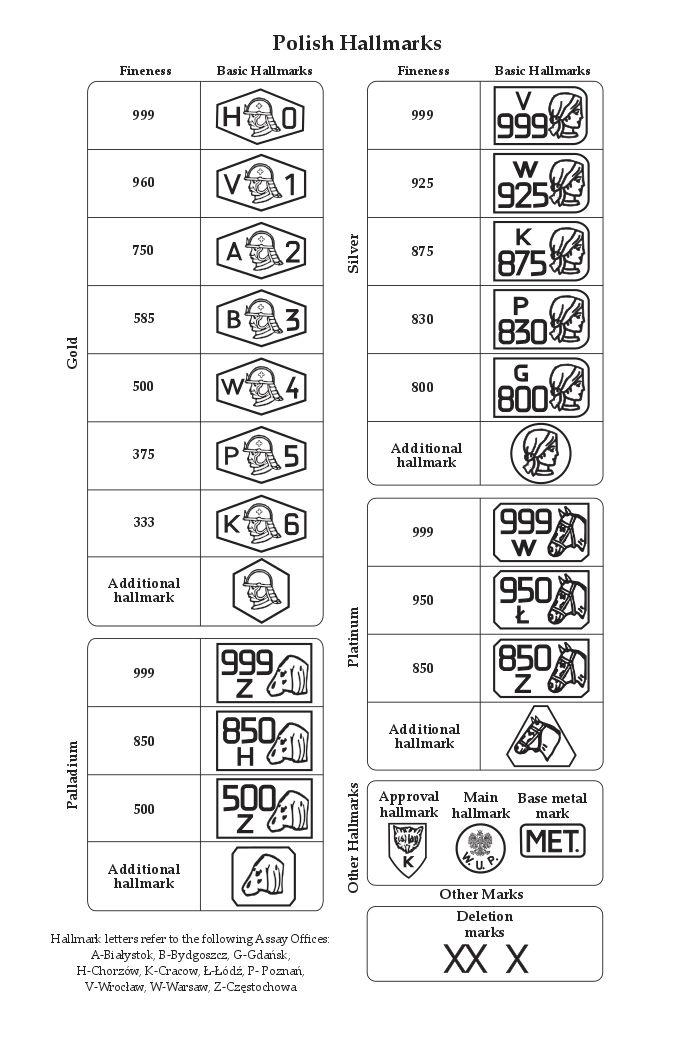

Hallmarks around the globe

In some countries, but not the US, a national assay office controls the testing of precious metal objects and marking purity. Depending on the country, a manufacturer’s declaration may make hallmarks compulsory, voluntary, or provided.

Most jewelry pieces are stamped with one or more hallmarks indicating the metal’s purity, the maker’s mark, or a brand name. The word “hallmark” originates in London, where starting from the 16th century, precious metals were sent for testing to the London Goldsmiths’ Hall. The Goldsmiths’ Company’s headquarters and the home of the Assay Office were The Goldsmiths’ Hall.

The French hallmarking system is organized on a compulsory basis. Enforced by the Hallmarking Act of 1973, all jewelry sold in the UK must carry a valid hallmark. Singapore and Japan are the only Asian countries with a voluntary hallmarking system and a national standard for precious metal purity. The Swiss Precious Metals Control Act of 23 December 1880 introduced a uniform system of Switzerland’s hallmarks.

Laser-engraved hallmarks

A logo, sequential numbering, and other complex engravings can be laser-engraved in various depths and sizes according to available space. The laser engraving is cleaned using a proprietary process that removes all vaporized residue.

The terms Laser marking, laser etching, and laser engraving are often used interchangeably, but there is a difference, and each process has its own applications.

Laser marking is achieved by moving a low-powered beam to interact with the surface, slightly altering the metal’s properties and appearance. It causes discoloration and creates high-contrast marks while leaving the surface intact.

Laser marking is less common in jewelry but is often used on stainless steel and titanium. It is one of the four processes: annealing, carbon migration, foaming, and coloration. There are three types of laser engraving: etching, deep laser engraving, and laser ablation. The difference between the three is the depth of the impact and the amount of metal removed. Laser engraving uses a laser beam to vaporize the surface physically, removing the metal and revealing a cavity with an image or text.